- Failure to issue a product recall can lead to litigation, which costs more than $700 billion a year in the U.S.

- Even multinationals are subject to product recalls!

- One secret to preventing product recall problems for brands is excellent communication

- Product recalls don’t always come from safety issues – small details can mean big problems

- Did you know that you can stay informed about recalls?

A product recall is a request for consumers to return an item that has been found to be defective, or which has safety issues that put buyers at a real risk of harm. Such recalls can happen with any product, from automobiles to toys to clothing. They are usually very costly, but litigation resulting from injuries, property damage, and deaths are even more expensive for manufacturers and sellers, costing U.S. industries more than $700 billion a year.

Recalls can be requested by a company voluntarily or by a federal government agency that oversees consumer products and safety. A voluntary recall is usually a result of testing or rising consumer complaints. The government may also request a recall after an investigation into these reports, or if an unsafe substance or material is discovered to have been used in the product.

The United States Consumer Product Safety Commission (CPSC) investigates complaints concerning unsafe products, and also issues recalls of defective goods or items that violate mandatory standards. In 2016, CPSC staff completed 428 cooperative recalls of products, an increase from the 410 recalls issued in 2015.

As with previous years, vehicles were responsible for the majority of CPSC recalls in 2016, including the largest auto safety recall in U.S. history; the ongoing, faulty Takata airbag inflator case, which has affected up to 100 million units, caused 11 fatal accidents and approximately 180 injuries. Other, non-food related items in the list of 2016’s ‘biggest’ recalls includes smoke/carbon monoxide alarms, McDonald’s Happy Meal fitness bands, dresser furniture and dehumidifiers.

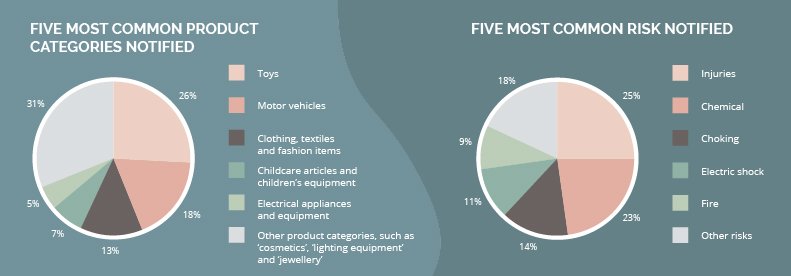

The 2016 figures from Rapex, the European Commission’s Rapid Alert System for dangerous non-food products reveal that the five most common product categories for notifications were Toys, Motor vehicles, Clothing, Electrical equipment and Childcare equipment.

Overall, the number of dangerous product notifications in Europe decreased in 2016, and now sits at 2044; returning to the level it was in 2009. Whereas, information received by Rapex concerning follow-up actions in response to notifications shows that this figure is almost double, at 3824. This data highlights the fact that national authorities are, increasingly, following up on notifications of dangerous products, with greater measures being taken throughout Europe to remove these products from circulation.

Differences in safety laws in the manufacturing country and the country of sale can inadvertently leave companies more vulnerable to recalls. A familiar, historical example of such differences from the twentieth century concerned the banning of lead-based paints for use on consumer goods. France, Austria, and Belgium instigated a ban as early as 1909, with the rest of Europe following by 1940. However, it wasn’t until 1978 that the United States passed similar laws, despite decades of warnings and evidence from health professionals. Obviously, it is up to the manufacturer to fully comprehend what is legal in their intended markets, but global differences can be complex, and lead to possible recall situations.

Since the days of playing catch-up over the banning of lead-based paints, many companies in the United States have taken a stronger stance on voluntary product withdrawals, as well as making production changes to avoid the need for recalls preemptively. In 2014, California-based health-care company Kaiser Permanente revealed that all of its $30 million worth of new furniture purchases would be free of chemical flame retardants, even though U.S. federal policy didn’t require this. Huge manufacturing companies and retailers, such as Walmart, Apple, HP, and Nike have stringent internal regulations regarding chemical usage in their products – rules that currently outstrip existing federal laws. One recent example of an organization taking action can be found in Greenpeace’s July 2017 announcement that Tesco will be committing to the conservation charity’s ‘Detox Campaign,’ and immediately removing hazardous chemicals from the supply chain of its fashion brand F&F.

That’s not to say reputable international companies are not immune to product recalls, even with rigorous design and production processes in place. Global fashion retailer Primark has issued three product recalls in 2017, with the latest instance affecting thousands of pairs of flip-flops, removed from shelves on 2 June, after being on sale for six months. Primark was made aware of the issue by a third party and discovered that the footwear contained higher than acceptable levels of the carcinogenic chemical chrysene, used in dark colored dyes. In addition to announcing the recall, the company has also suspended all outstanding orders from the factory in question and launched an inquiry into how the issue occurred.

The now notorious recall of Samsung Note 7s led to these phones being banned on planes after being tagged as potential explosives. Analysts believe that Samsung, in trying to bring forward the production schedule of its new flagship phones to rival Apple’s upcoming iPhone release, caused problems in the production process. Even non-injurious recalls can be disastrous for a company’s bottom line; in 2007, the Xbox 360’s ‘red ring of death’ signaled the console shutting down and being permanently inoperable. The resultant recall cost Microsoft around $1 billion.

Product recalls can also happen for seemingly innocuous manufacturing defects. In 2013, leading active wear brand, Lululemon had to recall a whopping 17% of women’s yoga pants that were too sheer, likely due to an attempt to cut on production costs; the brand ended up losing over $67 million.

How to avoid the products recall with quality control

Recalls generate negative buzz about a company or product and can damage their stock value. Manufacturing failures create distrust and adversely impact sales, costing the seller both money and reputation. Brands can and should better integrate quality control into their everyday operations to avoid these unexpected costs.

Having a Strong Recall Management Plan in Place

In 1991, not long after the launch of their brand, the U.S. car manufacturer, Saturn Corporation experienced a recall situation. Saturn discovered a problem centered on a flaw in the front seat recliner functions of their cars and immediately put their recall plan into action. 1480 vehicles were voluntarily recalled, dealers were briefed, and all Saturn customers received a letter, sent via overnight delivery, informing them whether their car was affected. Saturn’s recall plan was so efficient and well-received that they incorporated it in their advertising campaign, with one ad featuring a Saturn employee traveling to Alaska with a replacement seat; showing how far the company would go to satisfy their customers.

Forward-thinking companies understand the benefits of investing in recall management, or post-recall damage control, to mitigate the injuries to consumers and the company in case of product failure. In fact, if done correctly (as was the case with Saturn’s recall experience), a strong recall management plan can present unexpected advantages.

Obviously, Saturn’s recall didn’t affect a large number of customers, but, as a relatively new company, they would not have been able to deliver such a favorable outcome for both consumers and company reputation, if they didn’t have a strong recall management plan in place. It should come as no surprise to learn that Saturn had decided how they would respond to a recall situation more than a year before the launch of their first cars. Managers understood that anything that could threaten the long-term relationships they wanted to build with customers needed to be dealt with swiftly and efficiently.

While having these fail-safe strategies is crucial in the event of a crisis, implementing quality control improvements is a more sustainable, long-term solution for reducing recall risk and impact.

Enforcing a Reliable Quality Control Checklist

The quest for safer products begins at the design and development stage, with a comprehensive design risk assessment. This study will take into consideration the industrialization constraints of the product. Goods should then be evaluated through testing, inspection and certification. Determining product specifications and requirements prior to production, and providing a detailed quality control checklist, guides suppliers and lowers the possibility of manufacturing defects. Checklists can eradicate uncertainty by establishing clear parameters such as testing criteria to evaluate product quality. The key here is communication – it’s crucial that businesses ensure inspectors, testing staff and suppliers understand the requirements of each product.

Imagine you import tablet computers from China. Your staff knows that inspectors should check that the tablets are running the latest Android O operating system. However, your personnel assume inspectors are already aware of this. Your company also requires that the tablets contain 10 pre-installed apps such as Facebook, etc., but this information isn’t explicitly stated in your checklist or product specification. – In this particular case, because inspectors and your supplier were not made fully aware of your requirements, the tablets you receive could be running older versions of Android and not have the appropriate pre-installed apps.

Certain basic elements that should be checked on all goods include weight and dimensions, labeling, and color specifications. Companies should also ensure that both packaging and products are examined, and that all information presented to the consumer aligns with the items produced.

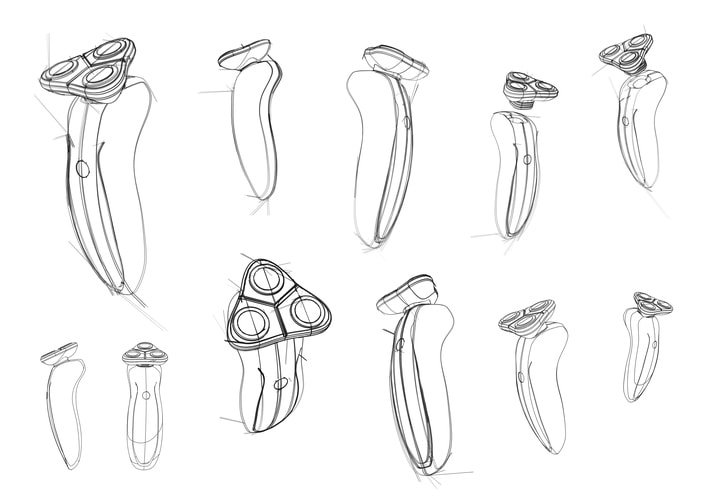

Take the example of a razor with a removable head. If the final product has a fixed head, it will not match the specifications on the packaging and customers will naturally return the item for a full refund. However, this won’t be the only impact to the company’s bottom line. Retailers will have to arrange product returns, there will be a voluntary recall, and an investigation will need to be launched to establish the cause of the problem. How did the item deviate from the original design? Was there an error in the manufacturing process of all items, or just certain batches of production? Did the packaging simply contain incorrect information? Or is there another reason for the issue? – For the manufacturer, these are all expensive questions, and problems that could have been avoided with a reliable quality control procedure.

As previously stated, some recalls can be the result of dangerous malfunctions or harmful substances being used in the production process, whereas others could be a lot more innocuous and simple to avoid. Discrepancies between the actual and expected dimensions of a product, or an unexpected variation in the weight of an item can trigger a significant product recall!

Stay Informed About Product Recalls

Once a recall is issued, you can expect to find the details of the recall on the company’s website and social media channels, as well as broadcast across mainstream media and news outlets. Product recall notices usually include a hotline or other contact information, as well as instructions on how to return the item and receive compensation. Consumers can also check their local or federal government agencies if they suspect a product they own has been recalled.

- For the U.S.: Consumer Product Safety Commission (CPSC) website

- For the European Union: Rapid Alert System (RAPEX) website

- For Australia: Product Safety Australia website

Here are a few useful tips to consider before you decide to purchase any new product or item, and some valuable information regarding packaging:

- The internet is a useful tool for researching product recalls that have been previously reported. Before you purchase an item, it’s a good idea to investigate if hazards have been reported in similar goods

- Once you are aware of previous recall situations, avoid buying products with similar designs or features

- Some major retailers, such as Ikea, Costco, and Tesco provide up-to-date information on recalled products. Check the news section of retailer websites for the latest advice on recalls and product repairs

- Before you dispose of any packaging, check to see if specific claims have been made about the product you’ve purchased. You should also check company websites for such announcements

- Manufacturers, retailers or distributors must provide valid contact information on the packaging, or on their website, in case of defects, malfunctions or discrepancies in claims relating to the item